Type of Transmission for Drive:

☞The motor power output available at the shaft is the transmitted to respective load through a transmission, media like chain, belt, gear, rope etc.

☞The choice is governed by most economical speed of motor. The dimensions and hence the cost of motor of given output is inversely proportional to the speed.

1. Belt drive:

This is a simple and cheap drive. Following types of belts are used: Leather belt, nylon

belt, terylene belt, rubberized cotton ply belt, hair belt.

The belt drives are of two types:

(1) Falt belt drive

(ii) V-belt drive

(i)Flat belt drive :

It is a long distance drive. The belt is generally made up of leather. Other material listed in above can also be used for belt. It is preferred in horizontal position. The slack side of the belt is kept at top so that natural sag increases the area of contact of the two pulleys.

Advantages:

1. Simple.

2. Greater flexibility.

3. Any desired speed ratio can be obtained.

4. When sudden load change occurs there is a tendency of belt to slip on pulley. This is better for both driving and driven member.

Disadvantages:

1. More space is required.

2. Maximum power it can transmit is 150 to 200 kW. So transmission capacity is limited.

3. It exerts side pull on bearing causing wear and tear of bearings. Following are the methods of transmitting mechanical power of motor to the load:

(a) Direct drive: The motor shaft (driving member) is directly connected to the driven member. E.g. motor-generator set in electrical lab.

☞A flexible coupling is used for such purpose. This can be used only where speed requirement of driven member matches with speed of driving member.

(ii) V-belt drive: It is suitable for motors with rating upto 450 kW. Because of wedge effect, there is increased friction between the belt and groove. This gives a better grip of about 3 times as that of flat belt.

Advantages:

1. Less wear and tear of bearings.

2.Short distances can be maintained.

3. Less noise.

2. Rope drive :

It is used for power ranges beyond the limit of V belt drive. It is a long centre drive. Main advantages of rope drive are negligible slip and ability to take sudden loads.

3. Chain drive:

It has no slip and no initial tension is present hence bending stress are eliminated. It can be used for high speed ratio (7:1). It is particularly suitable for damp and dirty conditions. The chain must run concentrically on the sprocket and at right angles to the shaft.

|

Chain Drive

|

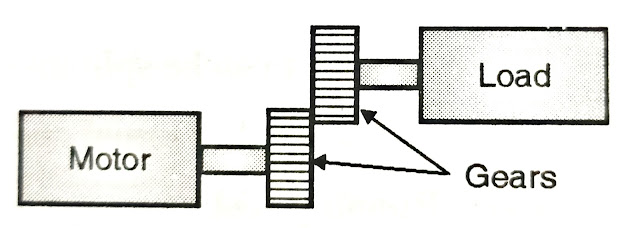

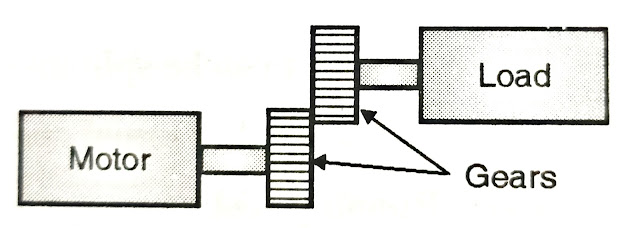

4. Gear drive:

☞It is a short centre positive rive. Proper alignment is very essential otherwise motor shaft may bend.

|

| Gear Drive |

☞Modern straight cut gears and particular variation found in worm reduction drive are common features in many machines such as cloth calendar.